Locate SALES AND SERVICE

AROUND THE GLOBE

Trained experts and original parts available from 250 distributor sales and service locations in 83 countries.

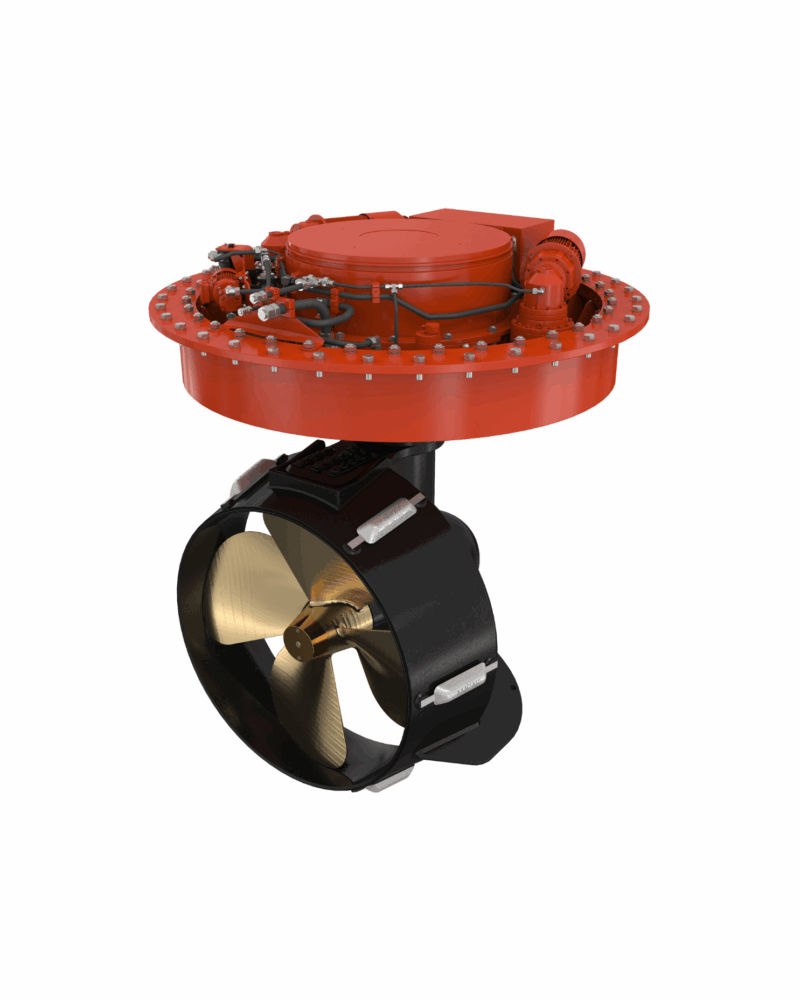

The Veth Integrated L-Drive is a compact, efficient, and quiet electric propulsion system designed for modern marine applications. With a low mounting height, advanced permanent magnet motor, and flexible configuration options, it delivers powerful performance while saving space and reducing noise.

Back to results

Trained experts and original parts available from 250 distributor sales and service locations in 83 countries.

BACK TO FILTERS COLLAPSE RESULTS

No distributors match the requested criteria, please widen your search.

Consent for Google Maps has been denied. Use the LOCATE button to see distributors or allow Google Maps. Adjust Google Maps Consent

Looking for a power transmission technology solution for your specific application? Twin Disc is more than ready to put horsepower to work for you.