Twin Disc Boosts Hydraulic Fracturing Applications

Twin Disc is proud that its products have helped propel the ongoing transformation of domestic energy production in the United States in recent decades. Our transmissions play an important role in the hydraulic fracking operations that have helped turn the U.S. into the world’s top producer of oil and gas.

Covering All the Bases

Universal Well Services, Inc., a leading provider of hydraulic fracturing services, wanted to upgrade its fracking fleet with longer-life replacement transmission for pressure pumping applications, so it reached out to Great Lakes Power Service Co. for help.

The recommended solution: Twin Disc’s purpose-built TA90-7500, a compact fracking transmission that could be used as a drop-in replacement for the units.

“Twin Disc builds durable transmissions for difficult applications,” said Harry Allen III, Vice President, Great Lakes Power Service Co. “That’s where they excel. Their engineering group did a phenomenal job making sure we had all the bases covered. Twin Disc provides technical expertise and resources including support on pumping stands, field support, and controlled integration.”

More Than 14K Operating Hours

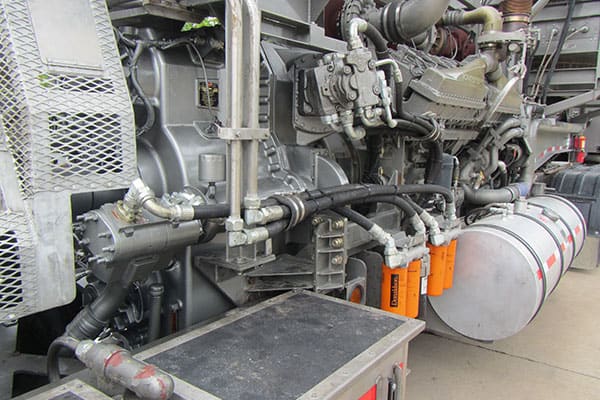

Consisting of a 9-speed coaxial power-shift transmission, the 7500 series transmission system provides up to 2,600 HP. Its compact design and less complicated plumbing make it easier to install in fracking rigs than other transmissions. It does not require a torque converter, cutting down on unnecessary weight.

The Twin Disc transmissions provide the robust horsepower needed for horizontal drilling applications in Marcellus Shale in the Appalachian Basin while providing great reliability. At last count, many of the 7500 series transmissions in the Universal Well rigs had been in use for 11,000 to 14,000 engine operating hours without failure.

Twin Disc has provided technology to meet the needs of oil and gas industry for most of our more-than century of service. Learn more about how our fracking transmissions, control systems and other solutions can meet your company’s needs. Click here to read the full case study.